Cleaning cloths may not be the first thing people notice when buying a new pair of glasses. Yet, these items are often the result of sophisticated printing and decorative processes which, to this day, remain largely manual. Here’s how Italian startup, Roboprint, partnered with TM Robotics, the distributor of Shibaura Machine robots, to develop an automated solution for the labour-intensive processes of detaching and handling eyeglasses fabric stock.

The end user, an Italian company called Centrostyle, manufactures a broad range of eyeglass cleaning cloths. The decoration of these items involves either pad-based printing machines or a process known as sublimation — a method of applying heat and pressure to transfer dye onto different materials.

The end user, an Italian company called Centrostyle, manufactures a broad range of eyeglass cleaning cloths. The decoration of these items involves either pad-based printing machines or a process known as sublimation — a method of applying heat and pressure to transfer dye onto different materials.

Centrostyle’s challenge related to the handling of these cloths following printing. Once printed, Centrostyle wrapped its decorated cloth patches in 220 cm-high reels weighing up to 50 kg. Handling these reels was not only a time-consuming process; but also created health and safety concerns, risking musculoskeletal disorders to crush injuries. What’s more, in addition to handling the reels, workers had to manually detach the individual cloths from the paper roll, stack them and package them. This labour-intensive process translated into significant costs for Centrostyle.

Centrostyle needed an automated solution. The company tasked Roboprint, an Italian start-up, with developing an automatic system for detaching and stacking the cloths. Roboprint turned to specialist robotics and automation consultant and distributor BBS ROBOT, who provided robots programming support through its Robotics Engineering Center. BBS Robot was then able to specify a solution supplied by TM Robotics’ Italian distributor Tiesse Robot. Here, the collaboration between Roboprint and Japanese robotics manufacturer, Shibaura Machine, began.

Getting a grip on automation

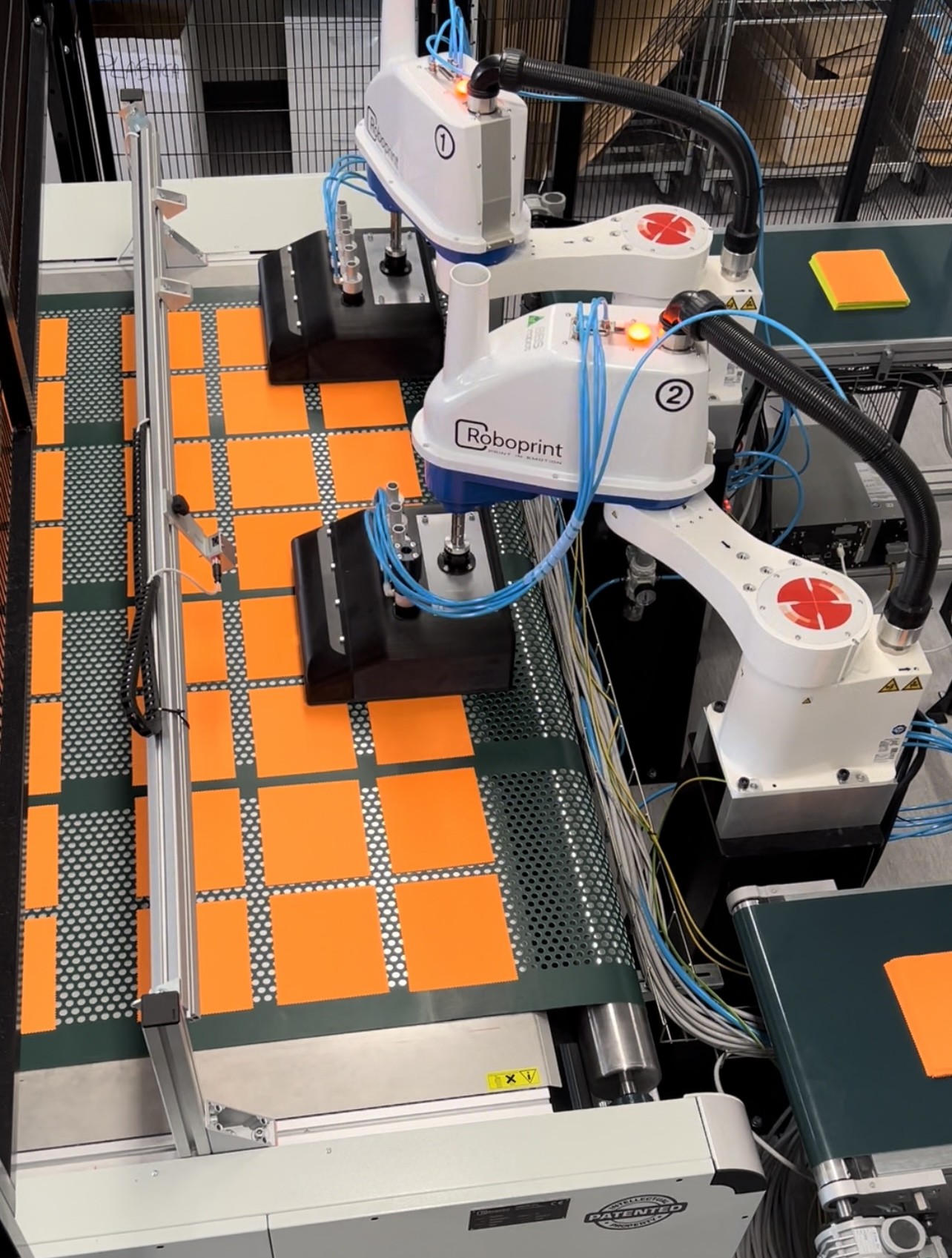

Roboprint designed and developed a new customised solution based on its flagship printing head technology. The Splitter, which is currently patent pending, consists of a reel-dragging system that automatically pulls and folds the paper roll at an acute angle, allowing the cloth patches to be detached by approximately four mm. A second conveyor belt then takes over the patches, completely detaching them from the paper substrate. From here, robots get a grip of the process.

The patches are fed to two THE600 SCARA robots from Shibaura Machine. The THE600 is the second largest model from Shibaura Machine’s extensive THE robot series — a market leading SCARA range designed and engineered in Japan.

Roboprint fitted the robots’ gripping hands with software-adjustable suction channels to collect the cloths one by one and stack them. These channels consist of perforated surfaces and are programmed to match the five cloth sizes produced by Centrostyle. Users can quickly select the desired cloth size on a PLC and the Splitter automatically activates the correct suction area in the perforated surface, collecting each cloth seamlessly.

The last step involves two conveyor belts that automatically collect stacks of patches that can then be boxed safely by an operator, eliminating manual handling hazards.

Smooth robot installation and operation

The Shibaura Machine THE600 SCARA robots were instrumental to the project’s success. These robots meet growing demand for fast-cycle automation, delivering optimal synchronised control and tracking precision. Despite its compact design, the THE600 has 60 per cent higher payload capacity than competing SCARA models in the same price range, making it the price-to-performance leader.

“Our Splitter system required a best-in-class robotic solution with best-in-class performance in terms of speed, precision and life span,” explained Valter Scolaro, R&D manager and owner at Roboprint. “The THE600 robotic arms supplied by Shibaura Machine distributor, TM Robotics met our expectations. They were easy to install and have operated reliably, at the correct speed, preventing vibrations and overvoltage.”

“With two four-axis SCARA robots working in parallel, the Splitter system can cover the desired work area while achieving high throughput and maximum safety, with the robots constantly communicating to prevent collisions” continued Scolaro.

A critical component of the robotic solution is the TS5000 robot controller from Shibaura Machine. This device features dedicated edge computing protocols combined with vibration analytic tools, generating predictive maintenance profiles unique to each application. Thanks to these capabilities, the TS5000 reduces downtime to a minimum.

Intuitive software

In addition to the new generation robot controller, Roboprint was appreciative of the TSAssist industrial robot programming tool. “The TSAssist software is very intuitive and enabled us to adapt the firmware on the PLC to ensure seamless communication with the robots,” explained Scolaro. “TM Robotics’ technical support team, which we were able to access thanks to our precious collaboration with BBS ROBOT’s robots programming support team and Tiesse Robot, was helpful and responsive, which translated into a smooth programming experience.”

TSAssist is a flexible and user-friendly programming tool that provides powerful assistance to all phases of automation, from planning and installation to enhancement. Users can upload and download program and parameter files, generate 3D simulations and perform checks while benefitting from updated graphical user interface. Programmers can also import their CAD files when building a 3D simulation of a work cell being designed.

Eye-catching results

Thanks to Roboprint’s solution, Centrostyle has achieved sizeable efficiency and productivity gains, reducing its yearly operating costs and saving over €300,000.

“Unlike sectors like automotive and logistics, robots are yet to be widely adopted in the printing industry,” commented Nigel Smith, CEO at TM Robotics. “Our collaboration with Roboprint, made possible by our Italian distribution Tiesse Robot and BBS ROBOT, demonstrates how industrial robots can help automate printing heads and other printing devices, driving efficiency and productivity and reducing cost throughout the supply chain.”

Shibaura Machine SCARA robots can support multiple printing and stamping applications, including injection moulding.

Roboprint plans to build on the success of the Splitter solution to continue collaborating with TM Robotics through BBS ROBOT and Tiesse Robot. “The technical support and service provided by TM Robotics has been outstanding. They always answer our questions with clear and competent answers,” concluded Scolaro. “We look forward to continuing this successful collaboration, living up to our promise to bring automation and robotics to the printing sector.”

To learn more about how Shibaura THE600 SCARA robots, visit TM Robotics’ website.