Our automation solutions aren't one size fits all. There are options available to customise all our Shibaura Machine robots to your needs, including those listed below.

For further information, request a catalogue.

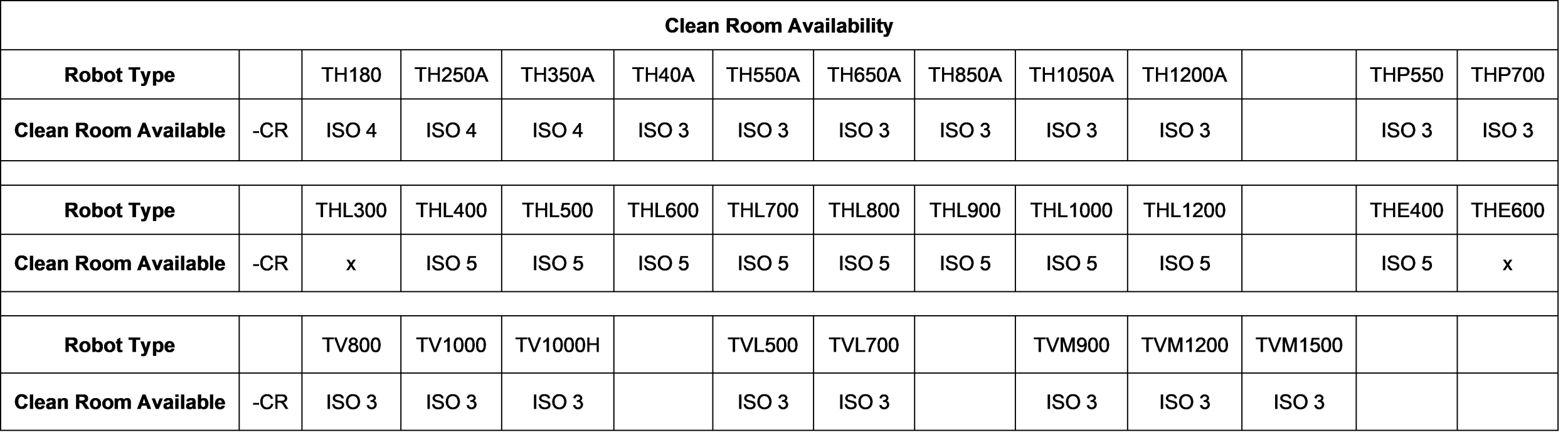

Cleanroom Rated Robots

Product Overview

A Cleanroom environment keeps the level environmental pollutants such as dust, aerosol particles, chemical vapors, and airborne microbes to a low level and are typical in electronic manufacturing, medical production environments, and some aerospace applications.

In terms of industrial robots, the cleanroom rating is defined as protecting to the environment from contamination by the robot, and in reverse, cleanroom rated robots are protected from the environment.

Typically, the lower the ISO number or lower the class number, the cleaner the rating.

All Shibaura Machine robots have clean room options available with many models being able to offer ISO Class 3.

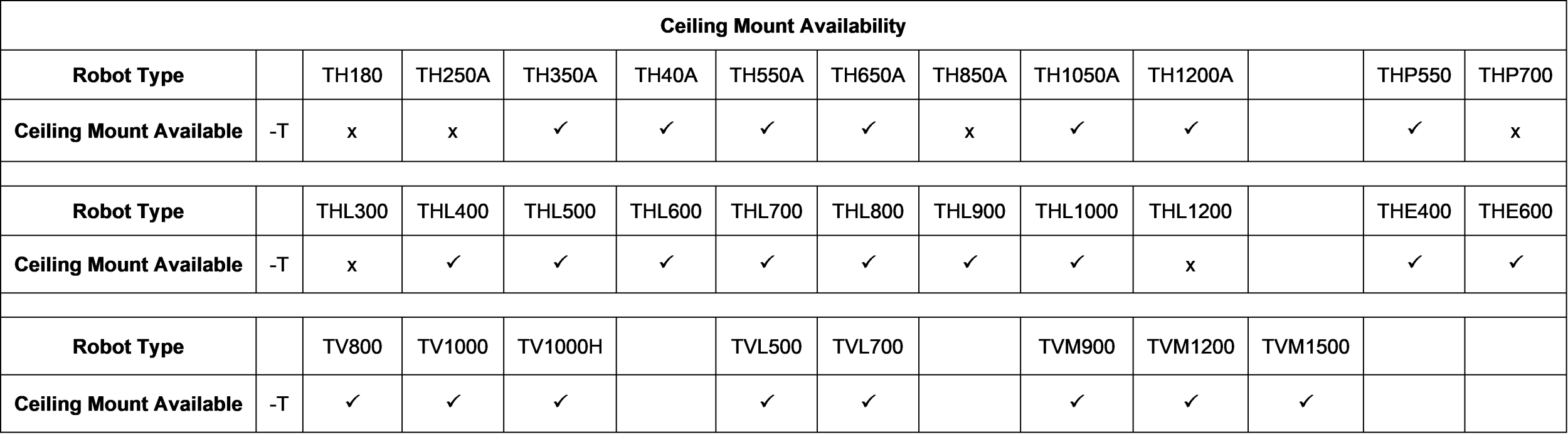

Ceiling Mounted Robots

Product Overview

Ceiling mount capabilities make the Shibaura Machine range of robots much more versatile. They save space in the robot cell, allowing valuable manufacturing real estate to be put to other uses.

This function is available as an option on nearly all of the SCARA range and all 6-Axis robots.

Examples of ceiling mounted models.

Some models, such as the TV and TVL 6-Axis robots, only require a parameter change to make them ceiling mountable.

See ceiling mounted robots in action in the video of the Hilcona pasta packaging line, below.

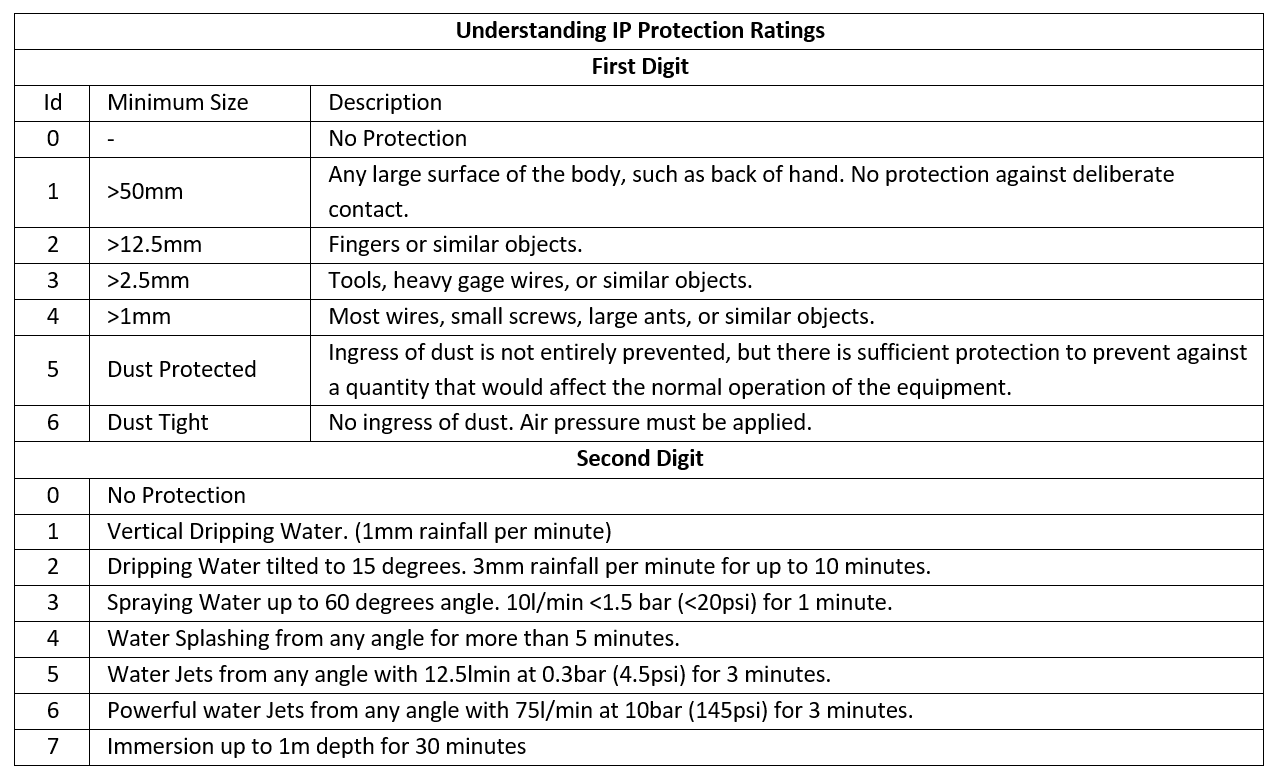

IP65 / IP67 Rated Robots

Product Overview

IP classifications show the resilience to dirt and water ingress for a particular robot model.

Industrial robots benefit hugely from the versatility offered by IP65 ingress protection, which allows them to be become part of the manufacturing process in food and pharmaceutical applications, rather than being limited to end of line packaging.

Many of the SCARA robots in Shibaura Machine’s range are produced in ‘off the shelf’ IP65 versions. Those that aren’t can take advantage of the company’s IP65 ‘hoods’, which provide similar advantages and can be retrofitted to existing robots.

IP Ratings:

- The first digit denotes the level of protection against ingress of solids.

- The second number denotes the level of protection against liquid ingress.

- A device which is IPx7, which protects against submersion in water, does not need to be IPx5 or IPx6 rated, for protection against water jets.

- A device that meets both standards will be indicated by listing both ratings, separated by a slash. For example, IPx5/IPx7.

Many of the Shibaura Machine SCARA and 6-Axis robots have the capacity to meet the standard of IP65.

The wrist of the TV1000H can work fully submerged underwater as it meets IP67 protection, as can be demonstrated in this video.

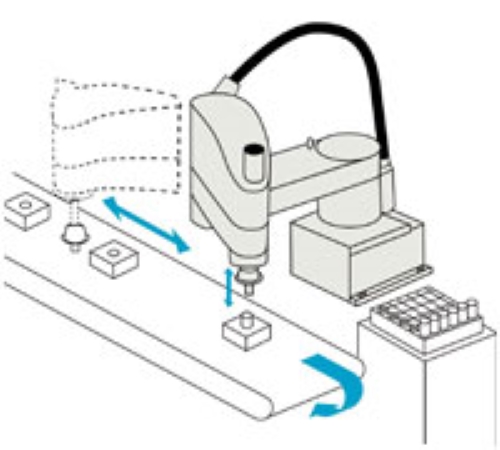

Extended Ball screw (Z-axis)

Product Overview

Every application is unique and occasionally the need arises to position the robot some distance from the product it is handling or reach into larger areas to either pick or place products. On these occasions, the capability to extend the z-axis stroke of a SCARA robot can be invaluable, allowing the user to opt for this cost-effective technology.

That this can be achieved without significantly reducing the payload, repeatability or speed of the machines simply demonstrates the versatility of the Shibaura Machine SCARA range.

For some OEM applications, specialized custom ball screw length options are available.

Jackets and Bellows

Jacket Product Overview

Jacket Product Overview

Ideal when using the robot in a hostile environment to protect from splashing or abrasive material, a jacket can be a more cost effective option than full IP65 ingress protection.

Alternatively, if the robot is being used within an application that requires constant cleaning, such as food handling, the jacket would also be an excellent option.

Bellows Product Overview

A simpler option than the jacket, bellows are available for many of the SCARA robots offered by Shibaura Machine. Bellows can be added to both the top and the bottom of the ballscrew to protect either the environment from contamination from the robot, or to protect the robot from contamination from the working environment.

Specifying bellows only creates a “simple clean” robot which will be protected from harsh environments, such as machine tending.

Bellows are required for models that specify IP or cleanroom ratings.

Examples of robots with bellows or a top cap.

Conveyor and Vision + Conveyor Tracking

Product Overview

All Shibaura Machine robots can work with vision as standard and all have the option to combine vision with conveyor tracking for inspection, packaging or assembly application.

Conveyor and vision synchronisation is simple with Shibaura Machine’s range of industrial robots. As a result, the end user can cut costs by ‘sharing’ a single camera between all of the robots on a conveyor.

Different shaped or coloured product can be recognised and sorted, as well as faulty parts when looking at inspection applications.

Shibaura Machine robots are capable of dual vision and conveyor tracking and so it enables parts to be picked from a moving conveyor as well as being placed onto a moving conveyor.

This video explains the details of conveyor tracking.

The net effect is greater efficiency and productivity, combined with savings in vision technology in a single, easy-to-implement package.

If you have questions about any of these options, please contact us.