Automated box opening robots

Product Overview

Box opener: CASi-IBOD for automated box opening

Introducing the CASi-IBOD (Intelligent Box Opening Device), a cutting-edge inline, pass-through box opening solution designed for automated box cutting, ensuring safe inventory extraction. By automating the box cutting process, the CASi-IBOD significantly reduces the risk of damaged products and workplace injuries commonly associated with manual box cutting methods.

Versatility is key with the CASi-IBOD, as it can handle boxes of any size and can process them in any order. Using advanced technology, the CASi-IBOD measures the dimensions of each incoming case, enabling precise cuts tailored to each box. This precision not only facilitates faster product removal but also enhances safety in the workplace, making the entire process more efficient and reliable.

Fullscreen YouTube Embed

Speed: Effortlessly cut up to 550 boxes per hour in a single configuration or boost productivity to 950 boxes per hour in the duo configuration (including lid removal)

Minimum labour: With only two operators needed to run the CASi-IBOD, reduce labour costs while maintaining high efficiency

Mixed-use capability: Adapt to various weights and sizes of boxes, ensuring versatility in your operations

Advanced safety features: Equipped with a blade wear monitor, intuitive HMI touch screen software, blade stop, side snugger, collision sensor, E-stops and other safety measures — reinforce workplace safety without compromising productivity

Efficient reporting: Easily retrieve activity reports from the system, providing valuable insights into operational performance

Customisable cutting specifications: Program precise cutting parameters to prevent product damage and enhance quality control

Streamlined testing and programming: Experience quick setup with an average of only five minutes required for product testing and programming

Flexible cutting options: Set programs based on the X, Y, and Z axis of boxes, featuring both 4-sided and 3-sided cutting capabilities

Protect human workers with automated box opening

Are you concerned about the safety of your human workers when it comes to box opening tasks? With the CASi-IBOD you can mitigate risks and protect your employees from potential harm. By automating the box opening process, CASi-IBOD keeps human workers away from sharp blades and repetitive motions that can lead to injuries. Ensure the well-being of your workforce while maintaining high productivity levels in your warehouse. Other safety features include:

E-stops

Light curtains

Impact sensor

Safety tunnels

Redefine efficiency

Manual box opening is not only hazardous but also time-consuming. The CASi-IBOD revolutionises your warehouse and factory operations by providing unmatched efficiency. With its advanced robotic arm and precision vision systems, CASi-IBOD swiftly and accurately opens boxes of various shapes and sizes. Say goodbye to bottlenecks and hello to streamlined efficiency and rapid order fulfillment. What are the features to improve production?

Automatic cutting tool changes: Software in the control system tracks blade use over time and will issue an alert when blades begin to get dull. Automating this step can significantly reduce downtime related to changing and replacing worn out blades

Automatic lid remover: The integrated Lid Remover is part of the CASi-AutoDecant solution. This system removes box lids automatically using an industrial robot. This improves operational efficiency by quickly preparing the box for decanting

Box flipper: The carton can be listed vertically from the conveyor and rotated to enable it to be flipped 180 degrees

Scan tunnel module: A scanning mechanism that can handle up to five-sided products. The module confirms product received and provides visibility for the customers state of inventory.

CASi-IBOD in action

The CASi-IBOD can cut a broad range of box sizes. It measures the size of every oncoming box in real-time, leaning on SKU matches to be seamlessly integrated into standard workflows.

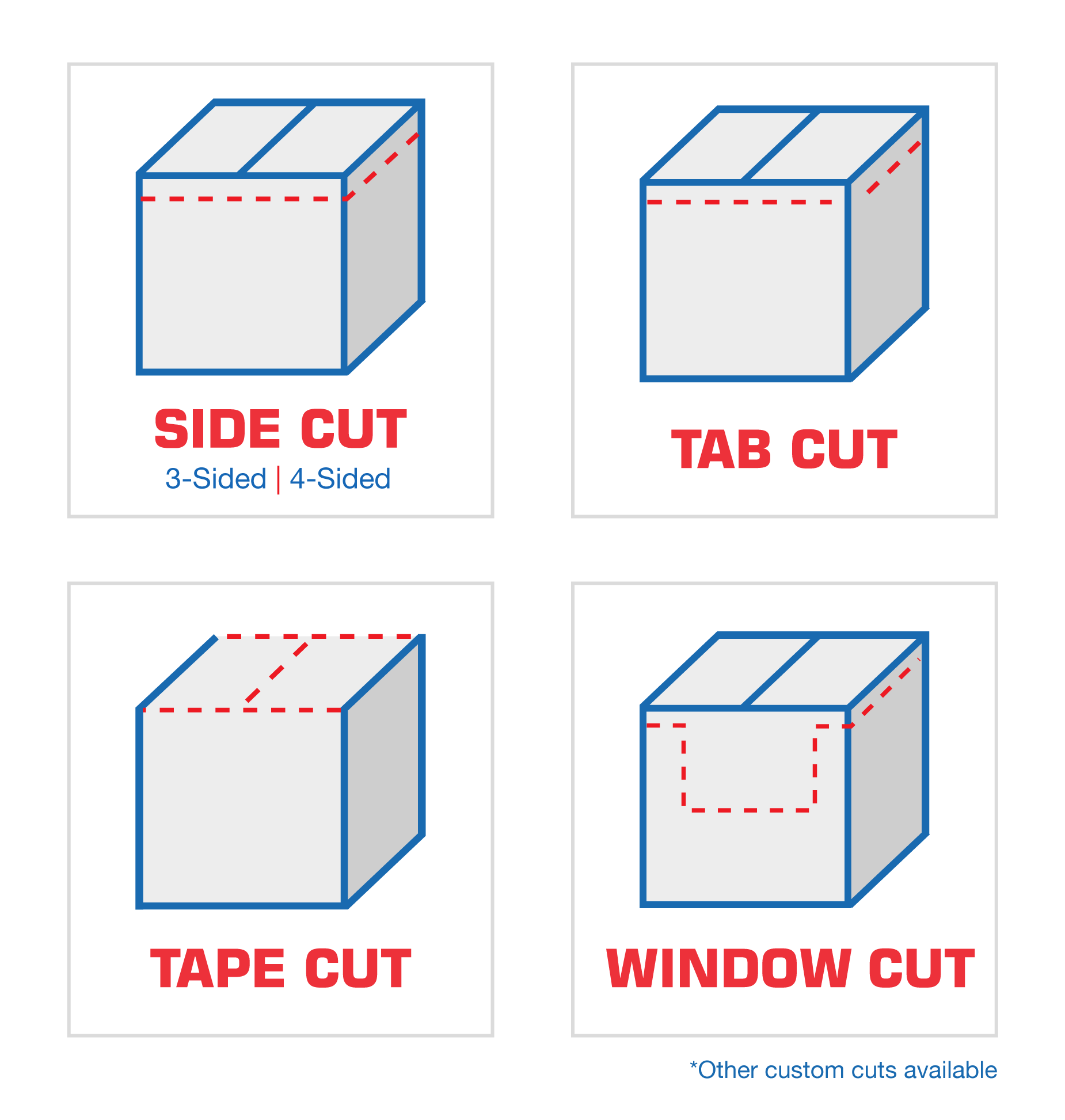

Side cut

Tab cuts

Tape cuts

Window cuts

Custom cuts available on request

Future-proof your warehouse management

Investing in CASi-IBOD is not just about improving efficiency and productivity; it's about future-proofing your warehouse operations or manufacturing facility. As technology continues to evolve, staying ahead of the curve is essential to remain competitive. CASi-IBOD represents the cutting edge of warehouse automation, equipped with the latest advancements in robotics.

The innovative system uses a Shibaura Machine robot arm to accurately control the movement of the blade. The model is one of a number of robots available from TM Robotics. Looking for standalone SCARA robots or another type of robot? View the full 6-axis or Cartesian range here.

By incorporating CASi-IBOD into your operations, you're not only optimising the present but also safeguarding your workforce and preparing for the challenges of the future.

Contact TM Robotics to discuss the CASi-IBOD or any other of our robotic systems. Speak to the team today.